Research groups

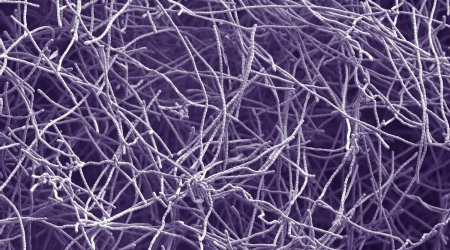

We are home to over 40 research groups, working on a variety of plant and microbial science research projects, led by our Group Leaders

Read about research groupsWe nurture a creative, curiosity led approach to answering fundamental questions in bioscience, and translate that knowledge into societal benefits

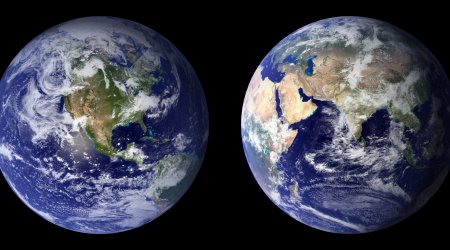

Our research aims to address global challenges and our knowledge of plants and microbes is used to answer fundamental questions, as well as having a significant impact on industrial biotechnology, society and global development.

We are home to over 40 research groups, working on a variety of plant and microbial science research projects, led by our Group Leaders

Read about research groups

Our four 'Institute Strategic Programmes' (ISPs) 2023 - 2028;

Read about our strategic programmes

Our scientific departments work across a range of disciplines including biology, chemistry, genetics and information technology

Read about our research departments

The John Innes Centre Publications Repository contains details of all our publications

Read about publications

We have a proven track-record over a 110-year history of economic and societal impact and our successes reach every UK household

Read about our commercial and societal impact

Science is an international endeavour. The very best science has, for centuries, relied upon the free exchange of ideas and people around the globe

Read about international

A range of state-of-the-art technology and research platforms to support scientists across all disciplines

Read about technology and research platforms

We have a range of scientific facilities to support scientists across all disciplines

Read about scientific facilities

An internationally recognised repository for the long-term curation and provision of crop germplasm resources

Read about germplasm resource unit

An open access journal from Cambridge University Press and the John Innes Centre

Read about quantitative plant biology

How you can get involved with us, from working with us, using our facilities or meeting our scientists at events

Read about get involved with us