Pea starch: an alternative material to plastic?

A team of researchers led by Cliff Hedley and Tanya Bogracheva at the John Innes Centre investigated the potential of producing ‘bio-plastic’ film made from dried pea seeds, as well as some related medical end-uses.

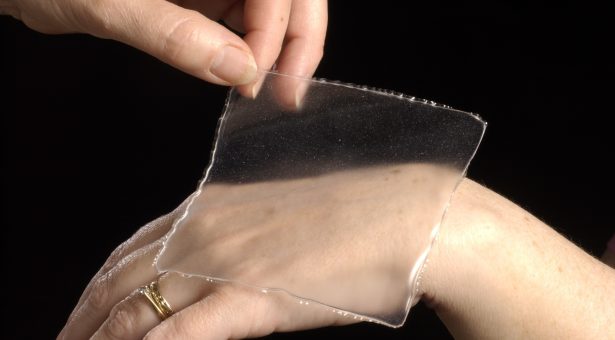

The films that Hedley and his team investigated were comprised of pea starch (an industrial waste product), glycerol and water.

The result was a film that presented excellent functional qualities such as strength, flexibility and elasticity.

In addition to finding that the films had the potential to be used for food packaging and agricultural mulches, Hedley’s team discovered a perhaps less obvious use: wound dressings.

The film’s ability to absorb water, as well as being non-allergenic (as opposed to some synthetic polymers), meant that the material was considered a suitable dressing for burns and some ulcers.

It was also found that anti-microbial materials could be easily incorporated into the film during its manufacture, which would help to prevent infection in the wound.

Despite being patented, the pea-derived dressing has not made it to the market. While it was very cheap to produce, as well as technically feasible, there was insufficient industrial interest, possibly reflecting a lack of awareness of the product in the most relevant emerging markets.

Currently, bio-plastics account for approximately 5-10% of the plastic market. However, with increasing concerns over the amount of plastic being released into the environment, as well as the reduction in oil resources (plastics currently consume 6% of global oil production), it is believed that the demand for replacing synthetic plastic packaging and films with renewable plant-derived materials will significantly increase.

Pea starch is an excellent bio-plastic candidate since the material is renewable and can biodegrade harmlessly under the right conditions.

There is also the additional benefit of reducing waste; it is well-known that pea seeds are a valuable source of protein for animal feed, but the additional value of using the starch by-product, which makes up approximately 50% of the mature pea seed, would limit wastage and improve the desirability of a multi-functional nitrogen-fixing crop.

Further reading

- Cano, A., Fortunati, E., Cháfer, M., Kenny, J.M., Chiralt, A., González-Martínez, C. (2015). Properties and ageing behaviour of pea starch films as affected by blend with poly(vinyl alcohol). Food Hydrocolloids. Elsevier, 48, 84–93. DOI: 10.1016/j.foodhyd.2015.01.008

- Hedley, C., Bogracheva, T., Topliff, I. (2005). U.S. Patent Application No. 11/569,801

- Lu, D.R., Xiao, C.M., Xu, S.J. (2009). Starch-based completely biodegradable polymer materials. eXPRESS Polymer Letters, 3, 366–375. DOI: 10.3144/expresspolymlett.2009.46

- Priya, B., Gupta, V.K., Pathania, D., Singh, A.S. (2014). Synthesis, characterisation and antibacterial activity of biodegradable starch/PVA composite films reinforced with cellulosic fibre. Carbohydrate Polymers, 109, 171–179. DOI: 10.1016/j.carbpol.2014.03.044

- Vieira, M.G.A., da Silva., M.A., dos Santos, L.O., Beppu, M.M. (2011). Natural-based plasticizers and biopolymer films: A review. European polymer journal, 47, 254-263. DOI: 10.1016/j.eurpolymj.2010.12.011