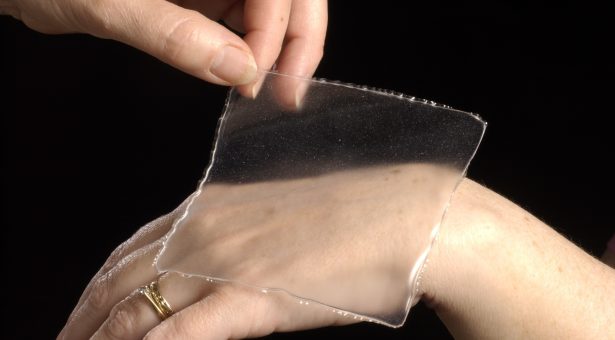

Wound dressing made from peas

A team of Norwich scientists has invented a new type of wound dressing – made from peas.

The scientists at the John Innes Centre were actually researching food packaging materials when they realised that one of their discoveries was more suited for another use.

Now the starch-based film is being trialled in a factory and there are hopes that it in future will be used by hospitals across the country.

The process has been patented by PBL, a Norwich-based technology and intellectual property management company. The company is jointly owned by the John Innes Centre, the Sainsbury Laboratory, and the Biotechnology and Biological Sciences Research Council.

The East of England Innovation Relay Centre, which helps companies find and exploit new technologies, has helped to match up PBL with Polymer Health Technology, a Welsh manufacturer of materials for wound dressings. Polymer Health Technology has already made the starch film on a small scale in its factory.

The next step is for it to be made on a larger scale, and PBL is looking for wound dressing manufacturer interested in taking it up.

The film was invented by Cliff Hedley, Tatiana Bogracheva and Ian Topliff at the John Innes Centre – though Mr Topliff has since moved to the Institute of Food Research.

Prof Hedley said: “These aren’t the sort of peas that you usually eat, which are smaller and sweeter, this is the round sided pea, which is usually fed to animals.

“It is the same species as the garden pea, there is just one gene that is different.

“We had a link project which was looking at packaging, and we observed a material that was not good for packaging but we thought could be used for something else, in this case wound dressing. We thought it might be better than some of the things that are used at the moment, for treating burns in particular

“You make a whole range of materials, and there will be some that don’t have the particular properties you want. You can either throw them out or see if there is something else that they are useful for.”

Starch makes up about half of a pea’s content, but is usually a by-product of making pea protein for the food industry. The structure of pea or bean starch means it makes better film than other starchy vegetables like potato or maize. And it is cheap and more environmentally sustainable than plastic films. Unlike plastic, it absorbs water, which can make it useful for treating wounds. The film’s other ingredients are water and glycerol.

Adam Hajjar, business development manager at PBL, said: “It is using a readily available natural product as opposed to some of the synthetic polymers, some of which can cause allergic reactions. They seem to have anti-microbial properties which could mean they could prevent infection in a wound.

“We think they might be suitable for burns and possibly some ulcers.”

The scientist’s project did also produce films that were useful for food packaging, and they are currently working on starch-based films for agricultural use, for example as a biodegradable mulch.